GUIDE TO BOLT FASTENERS

Béné Inox has been helping companies to design, maintain and optimise their fluid processes for over 40 years. We are a stainless steel product distribution specialist. We propose over 13.000 part numbers to industry and building professionals in our range of screws, bolts and nuts .

In this bolt fastener guide we have included everything that you need to consider to choose the bolts and nuts that best meet the requirements of your projects.

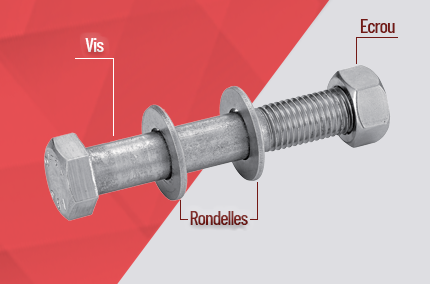

A bolt fastener is sometimes confused with a screw, however a bolt fastener is an assembly which includes a bolt or a threaded shaft as well as a nut. In most cases, this assembly also includes one or two washers.

A bolt fastener is an assembly system which goes through the parts that it fastens together. It is solid and robust when its nut is tightened strongly.

A bolt fastener is very strong meaning that it is perfect for use in parts which have high forces applied to them.

Multiple combinations are possible for a bolt fastener assembly.

The choices you make will depend on what you will use the bolt fastener for as there are a number of factors that you need to take into account to select the right one.

1. Application environment

Bolt fasteners are used to secure heavy loads in industry, assemble metal structures in the building industry and to build products (such as household white goods and furniture), amongst other things.

2. Bolt fastener components

A bolt, nut and washer or washers are the essential elements which make up a bolt fastener.

A bolt or threaded shaft is the main part of a bolt fastener .

Béné Inox proposes a wide range of stainless steel bolts as well as a guide to help you choose the bolt fasteners that are best adapted to your applications.

3. How to choose the right nut

Nuts guarantee the stability of an assembly up to the tightening torque that they are designed to withstand. There are many different types of nuts including standard nuts or more specific ones such as ring nuts , 3D hex nuts , self-locking PAL nuts for example.

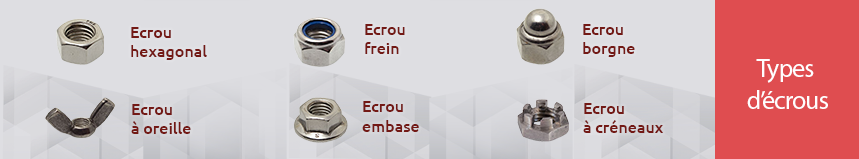

3.1 The main types of nuts :

- Hex nuts : are the standard nut type, their outer shape is hexagonal

- Due to their nylon ring, lock nuts are the best solution for making sure that nuts remain tight even if they are under tension or subjected to vibrations.

- Cap nuts : give an aesthetically pleasing finish and protect bolt or shaft threads. A cap nut is shaped like a dome meaning that it can cover up the end of a bolt or threaded shaft.

- Wing nuts or butterfly nuts : are often used for bolt fasteners that need to be assembled/disassembled frequently.

They can be tightened by hand.

- Base nuts : remove the need for washers as they have a greater load-bearing surface than standard nuts.

- Castellated nuts : secure assemblies as they are blocked into place on a bolt or shaft with a pin.

3.2 Material

We propose nuts in several materials to meet your project and application requirements:

- A1 stainless steel nuts

- A2 stainless steel nuts

- A4 stainless steel nuts

- A4 stainless steel varieties: A4-L stainless steel nuts and A4-L100 stainless steel nuts

- AISI 310 nuts

- Aluminium nuts

- Plastic nuts

3.3 Characteristics

When you choose a nut, you must take into account the following factors:

- Standards : a nut type corresponds to a standard which defines its dimensions.

- Dimensions (diameter and height) : a nut's diameter depends on the bolt/threaded shaft diameter. Its height is linked to its diameter, Béné Inox proposes nuts with heights from 0.5D to 3D.

- Threading type :

Nuts for ISO threading or UNC nuts for imperial bolt fasteners .

4. Washer choice

washer The main purpose of a washer is to protect the surface of the part which will be tightened and to guarantee that there will be good adherence when the bolt is tightened. A washer strengthens a bolt fastener by ensuring that the tightening force is spread evenly.

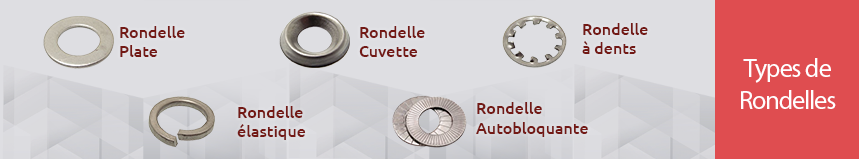

4.1 The main types of washers :

There are two types of washers :

- Thrust washers which protect the tightening surface and support pressure from the bolt :

> Flat washers are the standard type of washer, they increase the load-bearing surface of bolt heads or nuts.

> Cupped washers are best adapted for use with countersunk bolts

- Lock washers limit the risk of a bolt fastener becoming loose :

> Serrated washers (with teeth/toothed) reinforce the adherence of fasteners as their toothed part acts like an anchor.

> Spring washers behave like a spring and maintain the correct tightening of a bolt fastener even if stresses are applied to the bolt. There are several types of spring washers such as :

tapered washers , grooved washers , grower washers and curved washers ...

> Locking washers make it possible to effectively secure tightened bolt fasteners which are exposed to very high stresses and vibrations

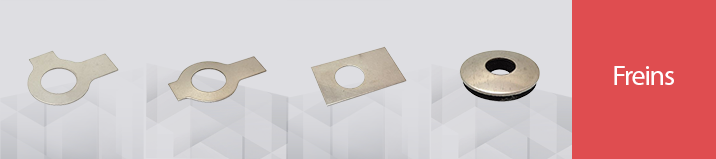

4.2 Specific washers: locking tab washers

Locking tab washers make it possible to block nuts as they prevent them from rotating. Once a locking tab washer has been tightened, part of it folds up against the side of the nut or the head of the bolt so that the nut cannot be turned.

4.3 Material

Washers are available in several materials:

- A1 stainless steel washers

- A2 stainless steel washers

- A4 stainless steel washers

- A4L-HV 300 stainless steel washers

- AISI 310 washers

- Aluminium washers

- Plastic washers

4.4 Characteristics

The following elements are essential for choosing the right washer to complete your bolt fastener :

- Standards : most of the washers proposed in our range comply with a specific standard.

- Dimensions (diameter and width) : like a nut, the diameter of a washer corresponds to the diameter of the bolt you are using it with.

Several washer widths exist. You should choose the width of your washer according to the load-bearing surface that you need to have when you tighten your bolt fastener.

5. Other fastening or assembly elements

Whatever you want to assemble, Béné Inox also proposes fixing elements which can increase the safety of your assembled parts.

5.1 Pins

Pins can be used to assemble parts that will have to be disassembled in the future.

They are often used in vehicle or machine construction in order to maintain, position and immobilise different parts within them.

Pins can be divided into two groups : locating pins and locking pins .

Locking pins can also be used as safety elements. There are several different types of pins in our range :

- Cylindrical pins which can be used to ensure the accurate location of parts or as locking elements.

- Conical pins which can be used to fix one part in relation to another. These are kept in place by wedging.

- Spring pins can also be used to stop parts from moving. This type of pin is kept in place in its housing due to its elastic expansion.

- V split pins are a type of locking pin. They are used with castellated nuts.

Beta pins or linchpins are types of split pins. They can be reused and are easy to remove.

5.2 Locating snap rings

Locating snap rings are removable assembly components. They can be used to create axial stops on axles or cylindrical bores.

Locating snap rings are used in many different industrial sectors (including the automotive industry, household white goods and machine sectors) with mechanical elements such as bearings, spacers and collars.

Locating snap rings are also known as circlips, several different types of circlips exist:

- Outer snap rings are circlips that can be assembled axially on a shaft or a transmission (generally in a groove).

- Inner snap rings are circlips that can be used for axial assembly in a cylindrical bore.

- Stop rings for axles can be assembled axially or radially on a smooth axle or in a groove.

>> Please click here to find out more about our range of bolt fasteners and screws

>> Contact us to find out more (our sales team will get back to you as quickly as possible)

�