GROOVED CONNECTOR SELECTION GUIDE

We are Béné Inox , your fluid processes partner, and we have been helping our customers to define their requirements and specifications for more than 50 years.

We have developed our groove fittings/connectors range to better meet our customer's requirements in particular for all seamless connection methods (i.e. methods that do not require welding) which are ideal for construction sites.

Application environment :

Grooved fittings/connectors allow you to create industrial piping networks completely safely, with maximum effectiveness!

Grooved connectors can be used for water treatment, fire detection, air-conditioning and heating networks or even compressed air, inert gases or industrial vacuum networks.

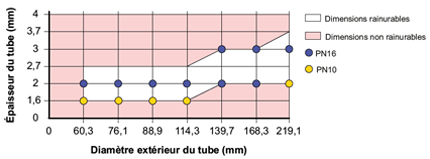

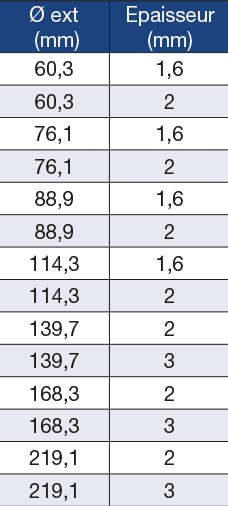

Range dimensions :

Our grooved fitting/connector range covers standard ISO diameters from 60.3mm to 219.1mm (323.3 mm is also available on request).

The special feature of this range is its pressure rating, which is linked to the piping thickness: PN10 or PN16.

Application conditions :

This product's main certifications are from the CSTB (the French Scientific and Technical Centre for Building) for construction uses and the ACS (French certification for drinking-water piping sanitary compliance).

Assembly :

This product's main certifications are from the CSTB (the French Scientific and Technical Centre for Building) for construction uses and the ACS (French certification for drinking-water piping sanitary compliance).

Equipment :

>> Click here to find out more about our groovers/grooving machines

- Groovers and groove rollers : these are mains powered and allow you to cold-work piping through knurling. These tools produce ST100 profile grooves.

>> Please click here to find out more about our piping range

- Piping : ISO piping, rolled and welded according to the EN10217-7 standard, in 1.4307 and 1.4404 stainless steel (equivalent to 304L and 316L stainless steel).

>> Please click here to find out more about our range of couplings

- Couplings :

Our couplings are made from cast iron or lined cast iron and come pre-assembled with EPDM or NBR gaskets.

Our couplings/clamps are ready to use. You just need to slide your grooved piping or grooved fittings/connectors into them and tighten them using their bolts.

>> Please click here to find out more about our fitting/connector and valve range

- Fittings/connectors and valves : our grooved connectors are made from 304L or 316L stainless steel. Our butterfly valves are always assembled with EPDM gaskets.

Flow rate :

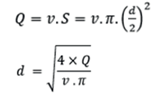

You will need to adapt the flow velocity of the fluids within your process to protect your installation, as well as to ensure acoustic comfort.

For example, it is generally recommended to use a flow velocity of 2-3m/s in a water network in order to avoid too turbulent flow.

Once you have defined the flow rate, you can establish the relationship between fluid velocity and cross-section. This will allow you to calculate the required piping diameter.

You can find our dimensioning table above.

>> Please click here to find out more about our range of grooved connectors

>> Please contact us to find out more on 0033 (0)4 78 90 48 22 or by filling in our request for information form here

�