OUR VALVE MOTORISATION GUIDE

At Béné Inox, we propose a wide range of 15 motor types in order to meet the requirements of many different applications and needs.

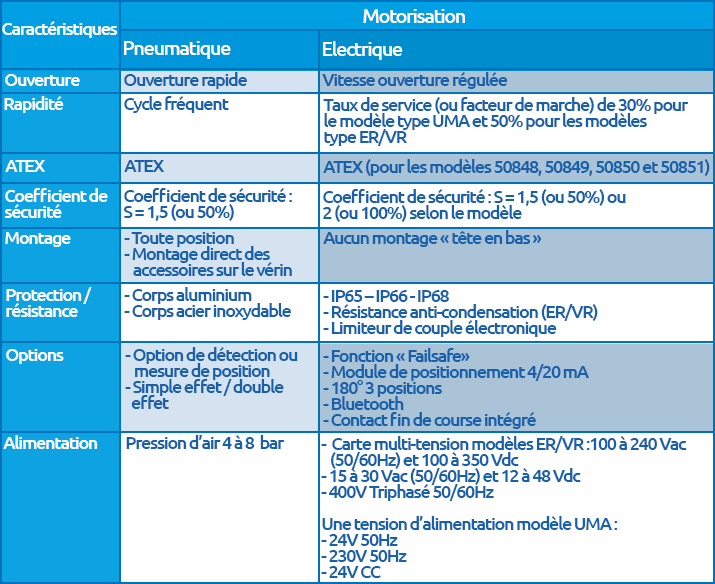

This range includes pneumatic and electric actuators . So our selection will allow you to find the solution that will meet your requirements, taking into account the specifications of the environment where you will locate the actuator and the fluid that you need to transport.

You can personalise your process motorisation with the following range of valves : ball valves , butterfly valves , diaphragm valves and gate valves . However, electrovalves and taper seat valves are sold with their motorisation included .

I - Actuators and their usage environment

You should take into account the following information to choose the most suitable actuator for your requirements :

1. Valve torque : this corresponds to the force that is needed to open/close your valve.

You need to take into account a safety coefficient of at least 1.5 of the maximum torque of the valve that you want to motorise to make sure that it will work correctly..

2. The valve's ISO mounting plate : the valve's ISO mounting plate must correspond to the actuator's mounting plate (e.g. F05 valve and F03/F05 actuator).

First, you need to make sure that the valve's ISO mounting plate (ISO 5211 standard) corresponds to the actuator's mounting plate (e.g. F05 valve and F03/F05 actuator).

Then, you need to check whether you need to add an adaptor to the valve's drive square to make sure it corresponds to the actuator's drive system.

3. Drive system : two types of drive are possible :

a. Pneumatic (drive pressure)

b. Electric (supply voltage)

4. Usage environment : this needs to be taken into account according to :

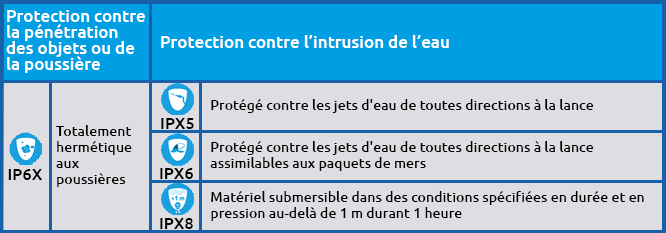

a. Protection rating

This only concerns electrical apparatus. This rating tells you about the type of environment an actuator can be used in.

>> Please click here for more information about protection ratings

Example of an IP68 model (model 50844) :

- This motor is completely dust-tight (IP 6 8)

- This motor can be submerged in water up to 1m for up to 1 hour (IP6 8 )

We propose the following protection ratings for our Béné Inox product range : IP65 / IP66 / IP68

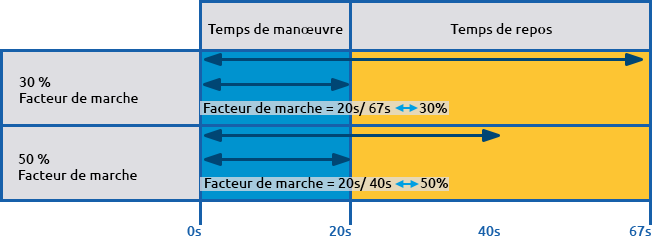

b. Usage frequency :

Unlike pneumatic actuators, electric actuators require a rest period in between each opening or closing movement to make sure that they work correctly.

You will need to choose between these two actuator types according to your process as well as your required valve opening/closing frequency.

For example, for an electric actuator with a 20 second on-time (opening/closing time) :

- If the actuator has a service rate/duty cycle of 30% --> its cycle will last for 67s

- If the actuator has a service rate/duty cycle of 50% --> its cycle will last for 40s

5. Temperature and pressure :

You should consider these two important points according to the fluid that you need to transport, your process and your application environment.

This range of products can withstand temperatures between -20°C and +80°C :

o Pneumatic actuator : -20°C +80°C

o Electric actuator "UMA" : -10°C +50°C

o Electric actuator "ER" : -10°C +55°C

o Electric actuator "VR" : -20°C +70°C

II - Motorised valve range

1. Motorisation range

2. Pneumatic actuators

You can either choose an actuator that is :

- Single acting (with one supplied air chamber): it is opened with compressed air and closed by springs.

A standard single acting actuator is normally closed (NC), but it is possible to modify it to be normally open (NO).

- Double acting (with two supplied air chambers): it is opened and closed by compressed air.

Complementary products :

- Position detectors :

Modèle 50830 >> | Modèle 50832 >>

- Solenoid valves :

>> Model 50811 | >> Model 50813

PPlease consult this product category to facilitate your pneumatic and air treatment connections.

3. Electric actuators

Depending on the electrical supply system installed in your building you could have one of the following types of current :

- Continuous current : an electrical current in which electrons flow continually in the same direction

- Alternating current: an electrical current in which electrons flow in an alternating manner in both directions in the circuit

Whichever model you choose, at Béné Inox we propose a complete range of alternating or continuous voltage actuators.

All of the actuators in this range come with multi-voltage cards, apart from model 50835 .

Do you need any more information ?

>> Please click here to find out more about our motor models

>> Please click here to find out product information for: Valves & accessories

>> Please click here to go to our product definition questionnaire for: Motorisation

>> Please contact us to find out more on 0033 4 78 90 48 22 or by filling in our request for information form here�