OUR CONNECTOR/FITTING SELECTION GUIDE

Simplify your product research by following our guide to how to select the most suitable industrial connector/fitting for your requirements :

Connectors/fittings are essential elements for connecting your fluid processes, assembling your pipe systems as well as for building industrial machines.

The functionality and assembly that you require are both important considerations for choosing the most suitable product.

This is why we have written this guide to help you to select the most suitable Béné Inox connector/fitting for your installation.

You should take the following points into account :

1. The application environment

First off all, you need to establish which standards are linked to your process :

- Industrial (standards linked to chemical, water treatment, construction industry sectors etc.)

- Food and Beverage industry (CE1935/FDA)

- Pharmaceutical and biotechnology (USP class VI / ASME BPE)

It is also important to note that: you will need to consider similar points when you are choosing the piping that you will use with your connectors/fittings.

Please click here to consult our piping selection guide for more information

2. Usage conditions and requirements

You need to take into account several factors to make sure you choose the right connector :

- Step 1 : Temperature & Pressure

These two parameters are crucial for defining the fluid that will be transported in your process.

If you do not consider these parameters correctly, there is a risk that your connector could become damaged and this damage could cause a leak.

Here are the different indicators that you should take into account :

o PN : nominal pressure (working pressure or operating pressure at 20°C)

o MAP : maximum allowed pressure (or pressure at which sealing will fail, first leak pressure). Please, read our specific document about this subject : MAP

Warning: temperature also plays a crucial role in the choice of the most suitable gasket to use with your connector/fitting.

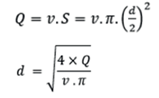

- Step 2: Flow rate for determining internal piping diameter (cross-section)

Recommended flow velocity is specific to each fluid type.

For example, for water, 2-3 m/s is recommended in a piping system to make sure that its flow is not too turbulent.

Once you have defined the flow rate, you can establish the relationship between fluid velocity and cross-section, so that you can calculate the piping diameter DN :

- Step 3: Fluid type

You will need to consider the type of fluid which will be transported through your connector/fitting so that you can check it is compatible with the materials used in your connectors and their gaskets.

In most cases, you should choose a 304 stainless steel connector for use in quite mild environments and a 316 stainless steel connector for use in more aggressive environments.

A connector's gasket plays a very important role in making sure that your process remains sealed/watertight. If a gasket falls apart, it could pollute the transported fluid and also cause the process to leak.

Due to this, material choice is extremely important. This is why it is necessary to check material chemical compatibility.

Please click here to read our documentation about this subject : indicative material chemical resistance .

You can also find information about the certification of our gaskets directly on our product information sheets.

- Step 4: Connection types

Connections can be made by welding fitting/connector ends (either by Butt Welding or Socket Welding), by screw assembly, by clamping (with flanges or clamp collars) or by press fitting.

It is also important to note that: you will need to consider all applicable standards as well as your future process maintenance requirements when you are choosing your connector/fitting type!

Our products comply with the following standards (listed by type of connector/fitting) :

1. Industrial fittings/connectors

a. European standards :

- Threaded fittings/connectors comply with ISO 4144 :

o BSP threading according to ISO 228-1 (but not compatible with ISO 7/1)

o BSP taper threading according to ISO 7/1 (but not compatible with ISO 228-1)

o We propose adaptors which allow you to pass from one threading standard to another (models : 5298 , 5299 )

- Union connectors (Range 51)

- Piping accessories (Range 52)

- Ferrule compression fittings :

o Single ferrule compression fittings comply with DIN 2353

o Double ferrule compression fittings

- Quick release couplings :

o Cam locking couplings comply with EN 14420-7

o Symmetrical Guillemin couplings comply with EN 14420-8

o Express couplings comply with NF E29-573

o Tankwagen couplings comply with EN 14420-6

- Flange connections comply with EN 1092

- Connectors for welding (elbows and reducers, Ts and pipe caps) comply with EN 10253

b. American norm :

- Threaded fittings/connectors comply with ASME B16.11 :

o NPT threaded according to ASME B1 20.1

o We propose adaptors which allow you to pass from NPT threading to ISO 7/ threading (models 5285 , 5286 )

- 3000 range fittings/connectors are also called oil fittings/connectors (Range 53)

- Quick release couplings :

o Cam lock couplings comply with U.S. MIL-C-27487

- Flange connections comply with ANSI B16.5

2. Food and beverage fittings/connectors :

- These comply with FDA and CE1935/2004 food and beverage related standards and with the general requirements of this industry sector (Ra < 0.8µm and minimised product retention).

o SMS standards comply with SS1145:2015 (Range 61)

o DIN standards comply with DIN 11851 (Range 62)

o Aseptic fittings/connectors with a tangential ring gasket comply with DIN 11864-1 , DIN 11864-2 and DIN 11864-3 , A shape (Range 62)

o CLAMP fittings/connectors comply with DIN 32676 or ISO 2852 (Range 63)

o MACON fittings/connectors (Range 64)

3. Pharmaceutical fittings/connectors :

- Clamp fittings/connectors comply with the American pharmaceutical standard ASME BPE

4. Press fitting fittings/connectors :

- You can find all of the information you need about this range of products by consulting our guide on this subject

Do you need any help?

>> Please contact us for more information on 0033 (0) 4 78 90 48 22 or by filling in our request for information form here

�

Connectors/fittings are essential elements for connecting your fluid processes, assembling your pipe systems as well as for building industrial machines.

The functionality and assembly that you require are both important considerations for choosing the most suitable product.

This is why we have written this guide to help you to select the most suitable Béné Inox connector/fitting for your installation.

You should take the following points into account :

1. The application environment

First off all, you need to establish which standards are linked to your process :

- Industrial (standards linked to chemical, water treatment, construction industry sectors etc.)

- Food and Beverage industry (CE1935/FDA)

- Pharmaceutical and biotechnology (USP class VI / ASME BPE)

It is also important to note that: you will need to consider similar points when you are choosing the piping that you will use with your connectors/fittings.

Please click here to consult our piping selection guide for more information

2. Usage conditions and requirements

You need to take into account several factors to make sure you choose the right connector :

- Step 1 : Temperature & Pressure

These two parameters are crucial for defining the fluid that will be transported in your process.

If you do not consider these parameters correctly, there is a risk that your connector could become damaged and this damage could cause a leak.

Here are the different indicators that you should take into account :

o PN : nominal pressure (working pressure or operating pressure at 20°C)

o MAP : maximum allowed pressure (or pressure at which sealing will fail, first leak pressure). Please, read our specific document about this subject : MAP

Warning: temperature also plays a crucial role in the choice of the most suitable gasket to use with your connector/fitting.

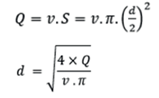

- Step 2: Flow rate for determining internal piping diameter (cross-section)

Recommended flow velocity is specific to each fluid type.

For example, for water, 2-3 m/s is recommended in a piping system to make sure that its flow is not too turbulent.

Once you have defined the flow rate, you can establish the relationship between fluid velocity and cross-section, so that you can calculate the piping diameter DN :

- Step 3: Fluid type

You will need to consider the type of fluid which will be transported through your connector/fitting so that you can check it is compatible with the materials used in your connectors and their gaskets.

In most cases, you should choose a 304 stainless steel connector for use in quite mild environments and a 316 stainless steel connector for use in more aggressive environments.

A connector's gasket plays a very important role in making sure that your process remains sealed/watertight. If a gasket falls apart, it could pollute the transported fluid and also cause the process to leak.

Due to this, material choice is extremely important. This is why it is necessary to check material chemical compatibility.

Please click here to read our documentation about this subject : indicative material chemical resistance .

You can also find information about the certification of our gaskets directly on our product information sheets.

- Step 4: Connection types

Connections can be made by welding fitting/connector ends (either by Butt Welding or Socket Welding), by screw assembly, by clamping (with flanges or clamp collars) or by press fitting.

It is also important to note that: you will need to consider all applicable standards as well as your future process maintenance requirements when you are choosing your connector/fitting type!

Our products comply with the following standards (listed by type of connector/fitting) :

1. Industrial fittings/connectors

a. European standards :

- Threaded fittings/connectors comply with ISO 4144 :

o BSP threading according to ISO 228-1 (but not compatible with ISO 7/1)

o BSP taper threading according to ISO 7/1 (but not compatible with ISO 228-1)

o We propose adaptors which allow you to pass from one threading standard to another (models : 5298 , 5299 )

- Union connectors (Range 51)

- Piping accessories (Range 52)

- Ferrule compression fittings :

o Single ferrule compression fittings comply with DIN 2353

o Double ferrule compression fittings

- Quick release couplings :

o Cam locking couplings comply with EN 14420-7

o Symmetrical Guillemin couplings comply with EN 14420-8

o Express couplings comply with NF E29-573

o Tankwagen couplings comply with EN 14420-6

- Flange connections comply with EN 1092

- Connectors for welding (elbows and reducers, Ts and pipe caps) comply with EN 10253

b. American norm :

- Threaded fittings/connectors comply with ASME B16.11 :

o NPT threaded according to ASME B1 20.1

o We propose adaptors which allow you to pass from NPT threading to ISO 7/ threading (models 5285 , 5286 )

- 3000 range fittings/connectors are also called oil fittings/connectors (Range 53)

- Quick release couplings :

o Cam lock couplings comply with U.S. MIL-C-27487

- Flange connections comply with ANSI B16.5

2. Food and beverage fittings/connectors :

- These comply with FDA and CE1935/2004 food and beverage related standards and with the general requirements of this industry sector (Ra < 0.8µm and minimised product retention).

o SMS standards comply with SS1145:2015 (Range 61)

o DIN standards comply with DIN 11851 (Range 62)

o Aseptic fittings/connectors with a tangential ring gasket comply with DIN 11864-1 , DIN 11864-2 and DIN 11864-3 , A shape (Range 62)

o CLAMP fittings/connectors comply with DIN 32676 or ISO 2852 (Range 63)

o MACON fittings/connectors (Range 64)

3. Pharmaceutical fittings/connectors :

- Clamp fittings/connectors comply with the American pharmaceutical standard ASME BPE

4. Press fitting fittings/connectors :

- You can find all of the information you need about this range of products by consulting our guide on this subject

Do you need any help?

>> Please contact us for more information on 0033 (0) 4 78 90 48 22 or by filling in our request for information form here

�