COUPLING COLLAR SELECTION GUIDE

We are Béné Inox, your fluid processes partner, and we have been helping our customers to define their requirements and specifications for more than 50 years.

We have developed our range of coupling and repair collars in order to connect piping and piping sub-assemblies and repair damaged pipes in a quick, safe and low-cost way !

Application environment :

This range requires very little tooling, you will only need a torque wrench. This makes it ideal for use on sites with very challenging connection environments.

The advantage of this range is that it can be used to repair damaged installations without you having to disassemble your piping network: so it can save you a lot of time!

These collars can be used in drinking-water networks (they have ACS French certification for drinking-water piping sanitary compliance) as well as water-treatment , air-conditioning and heating networks .

Range dimensions :

The coupling collar range is designed to connect ISO and ANSI pipes with diameters between DN40 and DN600 included.

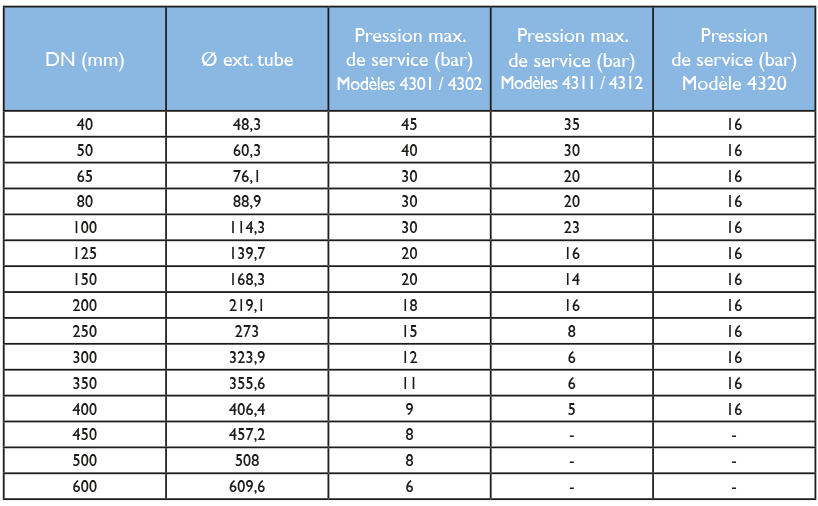

Their pressure rating depends on the coupling collar's diameter and can vary from one type of collar to another. For more information, please consult the table below :

Application conditions :

This coupling collar's main certification is the ACS French certification for drinking-water piping sanitary compliance.

Assembly :

Coupling collar assembly involves connecting two pipes together with the help of a coupling collar which includes a gasket.

The shape of the collar's gasket uses the pressure of the transported fluid to keep the gasket and the pipe in contact to seal the connection.

The collar is kept in place by torque tightening which ensures that the collar applies a specific pressure on the piping.

You must use the correct tightening torque to seal the assembly correctly: if you over tighten the collar, fluid will not be able to flow in the gasket and this will reduce sealing.

The operating temperature range for these products is between -20°C and +100°C included (EPDM and NBR gaskets).

Our products :

>> Please click here to find out more about non-locked hose coupling collars with EPDM gaskets

>> Please click here to find out more about non-locked hose coupling collars with NBR gaskets

- Non-locked hose coupling collars : these collars allow small axial movements in the attached piping, while allowing compensation for any ovalisation defects.

>> Please click here to find out more about axially locked hose coupling collars with EPDM gaskets

>> Please click here to find out more about axially locked hose coupling collars with NBR gaskets

- Hose coupling collars with axial locking : these collars have an anchoring system which attaches to a pipe when the collar is tightened and takes on some of the pipe's axial forces.

>> Please click here to find out more about repair collars

- Repair collars :

These coupling collars allow you to repair leaks in a specific area up to a maximum width of 100mm.

A repair collar can be directly installed on the damaged part of a pipe thanks to its two hinges.

These hinges allow it to be opened wide enough so that you can be wrap it around a pipe without needing to use any specific tooling.

It is available from DN40 to DN400 included.

Flow rate :

You will need to adapt the flow velocity of the fluids in your process to protect your installation, as well as to ensure acoustic comfort.

For example, it is generally recommended to use a flow velocity of 2-3m/s in a water network in order to avoid too turbulent flow.

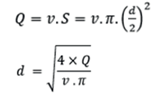

To calculate the piping diameter you need to calculate the cross-section of your piping according to the required flow rate and fluid velocity and establish the pressure drop (insignificant for this range of coupling and repair collars) using the formula below.

Please refer to the dimensioning table above, in the range dimensions section, to select the diameter that is most suitable for your application.

>> Please click here to find out more about our range of coupling and repair collars

>> Please contact us to find out more

�