SELECTION CRITERIA FOR INDUSTRIAL VALVES - BÉNÉ INOX

To choose the valves that are most suited to your needs it is crucial that you consider a number of different factors to guarantee that your processes work in an optimal and reliable way .

As an industry professional, you understand the importance of choosing the right valve to meet the specific requirements of your business sector .

This guide focuses on manual valves and has been specifically designed to help you to select the valves that you need for your applications. Manual valves play a major role in processes as they are essential elements for controlling and stopping the flow of liquids and certain gases .

If you understand the different characteristics of manual valves - whether you work in sectors such as chemical manufacturing, the petrol industry or the water treatment sector - you can make informed decisions and optimise your process systems.

This guide contains valuable information about the different types of manual valves that exist, their specific functionalities, as well as some practical advice which can help you to make the choices which are most suited to your applications and business field.

I - Ball valves

> 2-part valve female/female BSP or NPT | model: 58141/58145

> 3-part valve for butt welding (BW) - full bore | model: 58172

> Wafer ATEX ball valve with ISO mounting plate | model: 58249

Ball valves , are also known as spherical valves or ball plug valves and are characterised by several key points that set them apart from other valve types.

Their name comes from their hollow-ball shaped design which is the main element of this type of valve. The valve's ball has a hole in it which means that fluid can flow through it when it is in the open position.

These valves are designed so that they only need a 1/4 (90°) turn to go from a completely open position to being completely closed, and vice versa.

Several different versions of spherical valves are available: valves for welding (socket welding (SW) or butt welding (BW)), for threading (BSP or NPT threads) or valves with flanges.

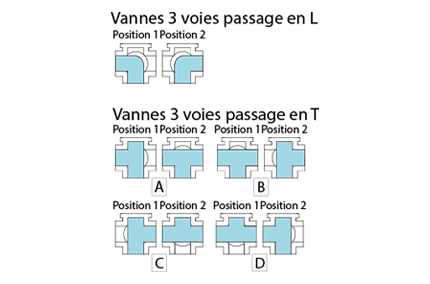

You can open or close a ball valve by moving their handle or wing handle, this rotation can be used to quickly and efficiently isolate parts of a piping network. The direction of a ball valve's straight handle is a clear visual indicator of whether the valve is open or closed. A 2-way ball valve can be used to isolate sections of piping. A 3-way ball valve can be used to deviate fluid flow or mix fluids together.

a - Advantages :

Stainless steel ball valves are an efficient and long-lasting choice for industrial fluid processes which require their component parts to have high corrosion resistance and high-pressure resistance (from PN55 to PN100).

Full bore ball valves can maintain fluid flow rates without causing pressure drops, while reduced bore ball valves (which are often used in high pressure applications) minimise pressure losses.

b - Application examples

Ball plug valves can be used in many different application areas such as :

- the distribution of compressed air, water and gas for industrial uses

- heating and cooling processes

- industrial cleaning

- the chemical industry/other industrial uses

- the petrol industry

- steam processes (when these valves have "GraFoil" carbon sealing)

Our product pages highlight our ACS compliant (French certification for drinking-water piping sanitary compliance), ATEX compliant (suitable for use in explosive atmospheres) and certified API 607 (fire safety compliance) valve products to help you with the definition of your requirements.

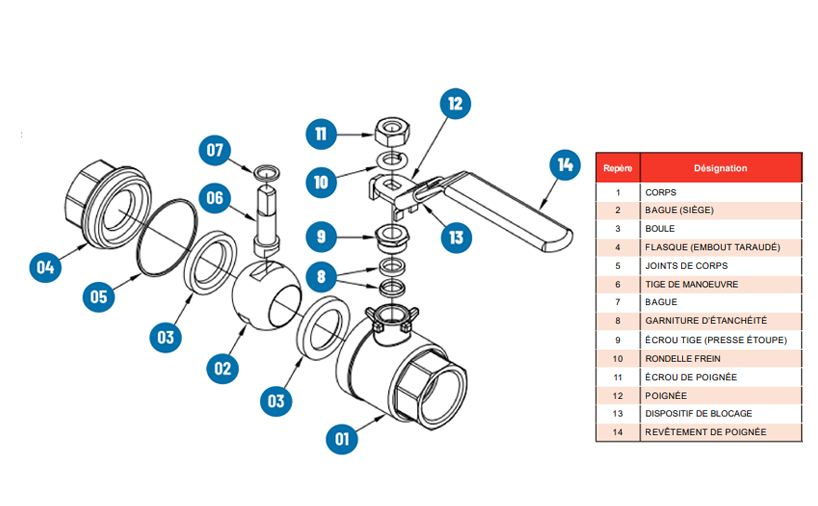

c - Ball valve component parts

II - Butterfly valves

> Butterfly valve with locating holes | model: 58419

> Butterfly valve with locating holes and handwheel gear reducer | model: 58419V

> Butterfly valve with threaded location holes | model: 58459

Butterfly valves are 1/4 (90°) turn valves which allow either all or nothing opening, or controlled opening. They are called butterfly valves due to their design: they contain a flat disk that is shaped like a butterfly and mounted on a shaft at the centre of the valve, a 'butterfly' that appears to move when the shaft rotates.

These valves are available in sizes up to DN300 with a handwheel gear reducer. The variety of sizes which are available in this range, in particular the large DN sizes, means that this type of valve is the first choice for a number of industrial domains, in particular those related to water.

a - Advantages

Butterfly valves are lighter and cheaper than other types of valve. They are also simple and easy to use.

They can be opened and closed easily with a 1/4 turn of their handle or handwheel, which will position the disk either in parallel to or perpendicular to the direction of fluid flow. A handwheel gear reducer makes it easier to control fluid flow rate, either linearly or by percentage control. This accessory can make a butterfly valve well adapted for applications which require frequent flow rate changes and which have a pressure between PN10 and PN16.

As butterfly valves have an in-line position, in relation to fluid flow direction, fluid retention is reduced, which in turn reduces the risk of any residue building up within them.

Butterfly valves are suitable for applications which require high fluid flow rates as they have a high flow rate capacity and can be used in pipes with large dimensions. They can also be assembled and disassembled quickly.

b - Application examples

Our range of butterfly valves is compatible with a large choice of gasket materials. This means that they can be used in many different application areas including:

- the transport of water containing particles or drinking water (they have ACS French certification for drinking-water piping sanitary compliance)

- chemical and manufacturing industries

- the supply of inert gases

- the food and beverage industry, in compliance with CE 1935/2004

Béné Inox's standard butterfly valves have a cast iron body and a stainless steel butterfly. We also propose a full stainless steel version of this valve (body and butterfly) for use with aggressive fluids.

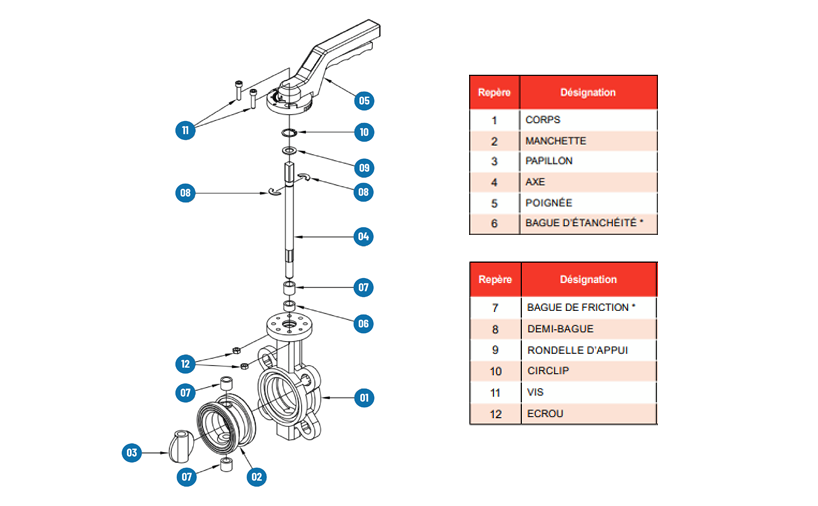

c - Butterfly valve component parts

III - Gate Valves

Gate valves are named after their central 'gate' element. This is a type of hatch with a closing element that is shaped like a blade and mounted vertically inside the valve.

When the 'gate' is open, the blade is completely removed from the path of fluid flow, allowing fluid to flow at its maximum rate. However, when it is lowered, the 'gate' completely blocks this space, stopping fluid flow efficiently.

a - Advantages

Gate valves are efficient whatever type of fluid your processes transport, even ones that contain particles or are very viscous. Depending on your fluid type, it is possible to use a cast iron or stainless steel valve body.

Gate valve design means that they will not retain any particles which is a big advantage as particle retention can damage a valve's opening/closing actions. This characteristic means that they are the best choice of valve for processes which transport fluids containing particles, viscous fluids or even powders, as butterfly valves or ball valves cannot be used for these processes.

In certain cases, when polymers are not resistant enough for the application in question, metal/metal sealing can be used to improve part resistance. However, metal/metal sealing does not provide as high a quality seal as when a sleeve gasket is used.

Gate valves are delivered with one-way sealing as standard. If there is any secondary pressure present in your process network you must choose a valve with two-directional sealing in order to prevent backflow.

b - Application areas

- Water treatment plants

- Chemical/Manufacturing Industry (powder transport)

- Paper making industry

- Heating/cooling water plants

- Mining and cement making

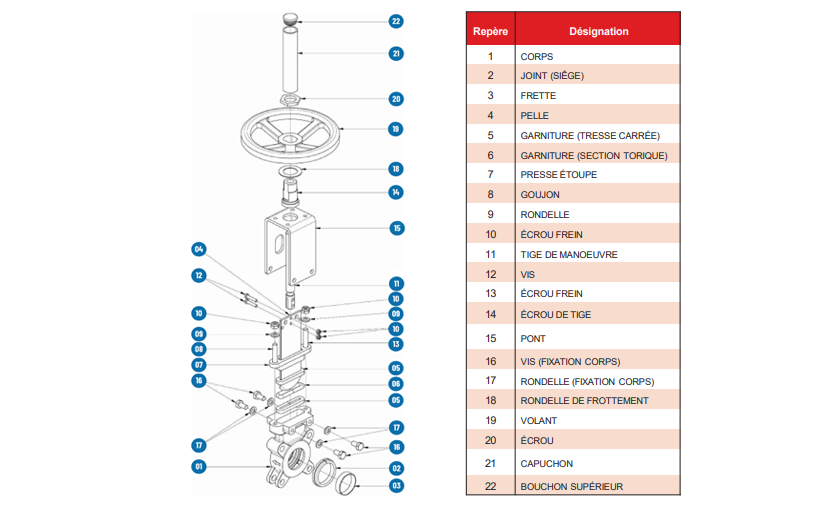

c - Gate valve components

IV - Diaphragm valves

Due to their simple and hygienic design diaphragm valves reduce fluid build-up and simplify cleaning processes.

The diaphragm part of these valves is made from a polymer material (in general EPDM, with or without a PTFE or TFM lining). These valves are opened and closed when their diaphragm is compressed by a piston. The diaphragm's elasticity allows a fluid to pass through it and then makes sure that it is sealed correctly.

a - Advantages

Only two parts of a diaphragm valve come into direct contact with the fluids which are transported through it and their design is optimised so as to avoid retention zones. This means that a diaphragm valve is the ideal choice for applications which involve the transport of sensitive products.

The diaphragm system means that watertight sealing is possible even when the transported fluid is a viscous fluid or a fluid containing particles.

This valve is extremely versatile so it can be used with different piping standards including: ISO, SMS, DIN, CLAMP and flanges.

Their slow opening/closing action helps to avoid water hammer and makes fluid flow regulation possible. Also, this type of valve is relatively light and small, both factors which mean that it is easy to install in different sized spaces.

Diaphragm valve maintenance (disassembly/diaphragm replacement) is very simple and does not require the complete disassembly of a piping network.

b - Application areas

Diaphragm valves are particularly adapted for use with aggressive or viscous fluids meaning that they are ideal for use in :

- the food and beverage, pharmaceutical and biotechnology industries

- the water treatment sector

- manufacturing industries

At Béné Inox, we also propose many other types of valve so that we can meet the requirements of all professionals. Please follow these links to discover Béné Inox's full range of industrial valves , food and beverage industry valves and pharmaceutical valves .

Béné Inox also proposes a complete range of motorised valves which includes pneumatic and electric actuators. Please click here to find out more information on this topic in our Guide to Valve Motorisation

Béné Inox has developed a specific decision-guiding questionnaire for valve selection. This can help you to identify the best valves for your processes.

However, if you require any additional information, our team of experts are available to help you. So please contact us via this form or by telephone on: +33 (0)4.78.90.48.22

�