GUIDE SUR LES NORMES DE RACCORDEMENT SMS, DIN, CLAMP

The food and drink industry is also called the food and beverage industry or the agri-food industry . It is made up of all of the industrial activities which transform raw materials produced by agriculture , animal husbandry and fishing into food and beverage products which are generally destined for human consumption .

As the elements used in fluid processes linked to this sector can come into contact with substances that will be ingested by humans , these parts must guarantee flawless hygiene levels.

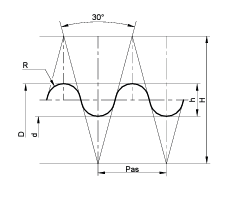

The products in our food and beverage industry range are designed to greatly reduce fluid retention in installations through their hygienic design, Ra <0.8 µm rugosity and round threading in accordance with the DIN 405 standard .

In addition to stainless steel accessories that are dedicated to the food and beverage industry , Béné Inox also proposes a wide range of CE1935/2004 certified gaskets which are suitable for contact with foodstuffs.

Gaskets which comply with this regulation are available in a number of materials: EPDM, FKM, NBR, silicon and PTFE.

At Béné Inox, our priority is to help our customers define their requirements.

This guide will help you to understand our products which are related to the different standards that are used in the food and beverage industry.

1. The SMS standard

The acronym SMS , or Swedish Metric Standard , refers to a collection of standards that have been developed by the Swedish Institute for Standards.

Principalement utilisée dans l'industrie alimentaire, la norme SMS is mainly used in the food and beverage industry and it specifies requirements relating to dimensions, materials and surface finishes for piping fittings/connectors, valves and other components used in applications which require extremely high levels of hygiene.

This standard was originally used in France by the dairy industry but it is now used across all sectors in the French food and beverage industry.

Features of the SMS standard

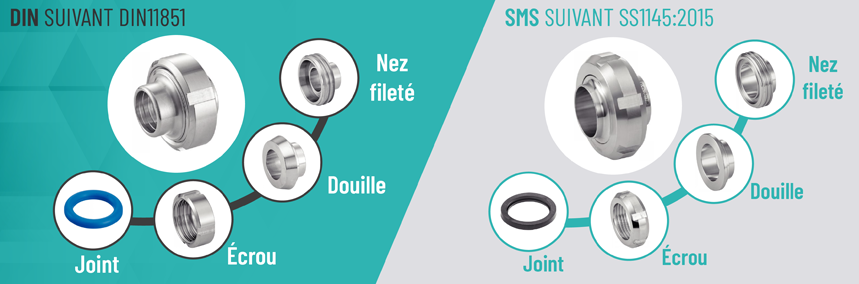

The SMS standard features a standard type of connector/fitting which complies with SS1145:2015 and is composed of three parts and one gasket.

Gaskets types:

The EPDM L-shaped gasket is considered to be a standard in our range of SMS fittings/connectors.

It can be used in many different applications thanks to its temperature resistance which ranges from -25°C to +120°C. But it cannot be used in contact with oils or fats.

SMS fittings/connectors are also compatible with square or half-ring gaskets.

Pipe types: The SMS standard requires the use of stainless steel pipes with a polished/brushed surface finish, this finish gives the steel an extremely shiny surface.

>> Polished/brushed SMS pipes

2. The DIN standard

The DIN standard (German Standards Institute standard) is a German standard which is used in the food and beverage industry, in particular in the brewing industry.

This standard regulates requirements concerning materials , dimensions and testing procedures for both products and components.

Features of the DIN standard

Like SMS connectors/fittings, DIN 11851 standard couplings are made up of three parts.

Gasket types: The standard NBR half-ring can be used for temperatures ranging from -25°C to +100°C.

- NBR half-ring connector gaskets

- Silicon half-ring connector gaskets

- FKM half-ring connector gaskets

Pipe types: The DIN standard allows pipes with unpolished or polished steel surface finishes, for easier cleaning.

- Unpolished DIN pipes

- Polished DIN pipes

3. Differences between the SMS and DIN standards

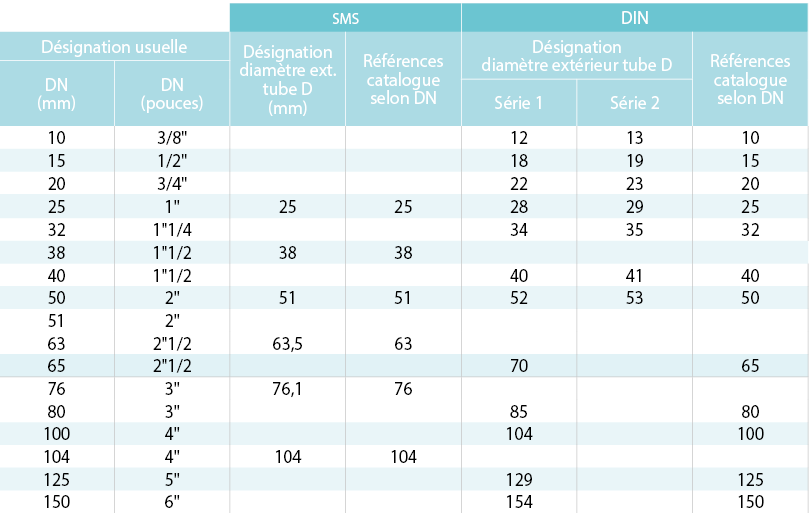

The main difference between the SMS and DIN standards are pipe and thread dimensions.

The design of SMS and DIN standard connectors/fittings is also different.

It is also possible to recognise the nut design for each of these standards. An SMS locknut always has 6 faces and quite a rounded profile due to its large chamfer (SMS standard 6-sided locknut ).

A DIN locknut can have 4 or 6 faces depending on its dimensions, but it has a more square profile due to its small chamfer (DIN standard 4-sided locknut ).

Where gaskets are concerned, L-shaped gaskets are specific to the SMS standard and cannot be used with DIN standard parts.

4. The CLAMP standard

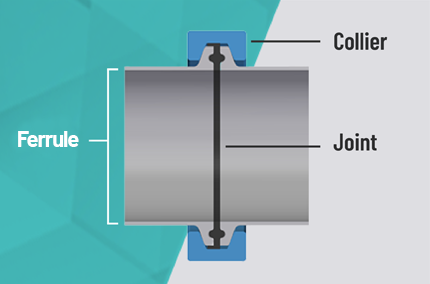

As its name suggests, parts linked to this standard allow clamping. This standard defines ferrule coupling side dimensions.

This type of connector/fitting is ideal for use in the food and beverage industry as it is easy to remove without tooling and is also easy to clean and sterilise .

The CLAMP standard is considered to provide the highest level of hygiene. When CLAMP collars are correctly tightened, their gasket lies flush to the ferrule, minimising fluid retention inside the connector/fitting.

Features of the CLAMP standard

A CLAMP connector/fitting is a part which is made up of several elements: 2 similar ferrule ends, a gasket and a clamping collar which is specifically designed for welded fittings/connectors.

The maximum allowable fitting/connector pressure is defined by the clamp collar.

There are several different types of CLAMP collars . According to their pressure resistance, certain CLAMP collars can be used in high pressure environments. Their articulation and design also vary, this can help to make their assembly easier.

- Double articulation CLAMP collars

- High pressure bolt CLAMP collars

- 3-part CLAMP collars

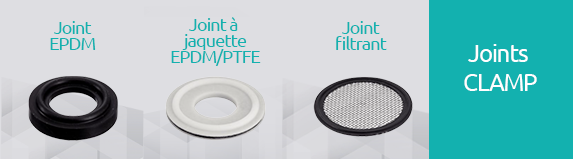

EPDM, FKM, PTFE, silicon or PTFE jacketed gaskets are all gasket materials which can be used with CLAMP connections/fittings .

In general, CLAMP standard gaskets have a lip to keep them in contact with the ferrule, making their assembly easier.

However, the smaller diameter gaskets (for micro CLAMPs and mini CLAMPs) do not have a lip.

- EPDM CLAMP gaskets

- EPDM/PTFE jacketed CLAMP gaskets

- Filtering CLAMP gaskets

The specificity of CLAMP fittings/connectors is that they exist in SMS, DIN (DIN 10357) and ISO (ISO 1127) pipe dimensions.

CLAMP ferrules are made out of AISI/316L stainless steel and CLAMP collars out of AISI 304 stainless steel.

The CLAMP standard is specifically designed for welded fittings/connectors which are used in the food and beverage industry.

CLAMP fittings/connectors are easy to install, maintain and replace if a leak occurs.

Please contact us for more information on 0033 4 78 90 48 22 or by filling in our request for information form here

�